News

Meeting the Ethanol Challenge

Published April 23, 2007

FOR IMMEDIATE RELEASE

San Diego Supercomputer Center

|

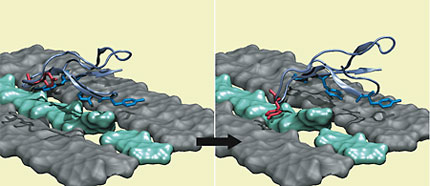

Scientists used an SDSC supercomputer to help improve cellulose conversion to ethanol. Their "virtual molecules" show how the enzyme complex may change shape to straddle a broken cellulose chain, gaining a crucial foothold to digest cellulose into sugar molecules, which can then be fermented into ethanol. Image courtesy of Ross Walker and Amit Chourasia, SDSC and Michael Crowley and Mark Nimlos, NREL. |

Termites and fungi already know how to digest cellulose, but the human process of producing ethanol from cellulose remains slow and expensive. The central bottleneck is the sluggish rate at which the cellulose enzyme complex breaks down tightly bound cellulose into sugars, which are then fermented into ethanol.

To help unlock the cellulose bottleneck, a team of scientists has conducted molecular simulations at the San Diego Supercomputer Center (SDSC), based at UC San Diego. By using "virtual molecules," they have discovered key steps in the intricate dance in which the enzyme acts as a molecular machine -- attaching to bundles of cellulose, pulling up a single strand of sugar, and putting it onto a molecular conveyor belt where it is chopped into smaller sugar pieces.

"By learning how the cellulase enzyme complex breaks down cellulose we can develop protein engineering strategies to speed up this key reaction," said Mike Cleary, who is coordinating SDSC's role in the project. "This is important in making ethanol from plant biomass a realistic 'carbon neutral' alternative to the fossil petroleum used today for transportation fuels."

The results were reported in the April 12 online edition of the Protein Engineering, Design and Selection journal, which also featured visualizations of the results on the cover.

A convergence of factors from looming global warming to unstable international oil supplies is driving a surge in renewable biofuels such as ethanol, with worldwide ethanol production more than doubling between 2000 and 2005. To date, corn has been the favorite ethanol source. While good news for farmers, corn prices have doubled in the past two years, and consumers worldwide are feeling the pinch as food prices climb.

A far better source is to produce ethanol from cellulose, easing pressure on food supplies and yielding greater greenhouse gas benefits. The fibrous part that makes up the bulk of plants, cellulose is the cheapest and most abundant plant material, from corn stalks left after harvest to wood chips from papermills and fast-growing weeds.

"Our simulations have given us a better understanding of the interactions between the enzyme complex and cellulose at the molecular level -- the computer model showed us how the binding portion of this enzyme changes shape, which hadn't been anticipated by the scientific community," said first author Mark Nimlos, a Senior Scientist at NREL. "These results are important because they can provide crucial guidance as scientists formulate selective experiments to modify the enzyme complex for improved efficiency."

What the scientists found in their simulations - a "virtual microscope" that let them zoom in on previously invisible details -- is that initially the binding part of the enzyme moves freely and randomly across the cellulose surface, searching for a broken cellulose chain. When it encounters an available chain, the cellulose itself seems to prompt a change in the shape of the enzyme complex so that it can straddle the broken end of the cellulose chain. This gives the enzyme a crucial foothold to begin the process of digesting or "unzipping" the cellulose into sugar molecules.

To the scientists, the simulation is like a stop-motion film of a baseball pitcher throwing a curveball. In real-life the process occurs far too quickly to evaluate visually, but by using the supercomputer simulations to break the throw down into a step-by-step process, the scientists can see the precise details of the role of velocity, trajectory, movement, and arm angle. To undertake the large-scale simulations, the researchers used the CHARMM (Chemistry at HARvard Molecular Mechanics) suite of modeling software.

According to the researchers, an accurate understanding of the key molecular events required the simulations to run for some six million time steps over 12 nanoseconds (a nanosecond is one billionth of a second) in order to capture enough of the motion and shape changes of the enzyme as it interacted with the cellulose surface.

This is an extremely long time in molecular terms, and the computation-hungry simulations ran for some 80,000 processor-hours running on SDSC's DataStar supercomputer.

Also participating in the study were Michael Crowley, William Adney, and Michael Himmel of the Department of Energy's National Renewable Energy Laboratory (NREL); James Matthews and John Brady of Cornell University; Linghao Zhong of Penn State University; as well as Ross Walker, and Giridhar Chukkapalli of SDSC.

The research was partially funded by the Department of Energy's Biomass Program and the National Science Foundation.

Comment:

Mike Cleary

858-822-0880

mcleary@sdsc.edu

Mark Nimlos

303-384-7704

mark_nimlos@nrel.gov

Media contact:

Warren Froelich

858-822-3622

froelich@sdsc.edu

Paul Tooby

858-822-3654

ptooby@sdsc.edu

Categories

Archive

Related Links

• Protein Engineering Design and Selection

• National Renewable Energy Laboratory

• Cornell University

• Penn State University

• Department of Energy's Office of the Biomass Program

• San Diego Supercomputer Center (SDSC)